Menu

Close

Soft touch lamination is a special type of finish for paperboard packaging materials to give them a unique texture and appearance. This type of lamination is a thin layer of soft, velvet-like material on the surface of the paperboard, which creates a tactile sensation when touched. Soft-touch laminated boxes are packaging boxes finished with soft-touch lamination. The usage of these boxes is for a variety of purposes, including retail packaging, gift packaging, and product packaging. They are particularly popular in the cosmetic and luxury goods industries because they offer a premium look and feel that enhances the perceived value of the products. The soft-touch lamination process involves coating the paperboard with matte plastic film. This plastic film mixes with a special chemical compound that gives it a soft, velvety texture. The resulting finish is not only aesthetically pleasing but also adds a layer of protection to the packaging, making it more durable and resistant to wear and tear. Additionally, one of the key benefits of soft-touch laminated boxes is their ability to create a tactile experience for the consumer. When you touch the box, the soft, velvety texture adds a sense of luxury and exclusivity to the product inside. Finally, the soft touch finish combines with other printing techniques, such as foil stamping or embossing, to create an even more striking visual effect.

| Sizes | Offered in all custom shapes and sizes |

| Paper Stock | 14pt, 16pt, 18pt & 24pt White SBS C1S C2S |

| Printing | Digital, Offset and Screen Printing |

| Options | Matte, Glossy, Spot UV, Aqueous Coating and Embossing, Debossing |

| Extras | Flaps, Ribbons, thread handles, gold foiling, silver foiling |

| Quantities | Short run and Bulk orders are accepted |

Payments:

![]()

| Sizes | Offered in all custom shapes and sizes |

| Paper Stock | 14pt, 16pt, 18pt & 24pt White SBS C1S C2S |

| Printing | Digital, Offset and Screen Printing |

| Options | Matte, Glossy, Spot UV, Aqueous Coating and Embossing, Debossing |

| Extras | Flaps, Ribbons, thread handles, gold foiling, silver foiling |

| Quantities | Short run and Bulk orders are accepted |

Payments:![]()

Soft touch lamination is a special type of finish for paperboard packaging materials to give them a unique texture and appearance. This type of lamination is a thin layer of soft, velvet-like material on the surface of the paperboard, which creates a tactile sensation when touched. Soft-touch laminated boxes are packaging boxes finished with soft-touch lamination.

The usage of these boxes is for a variety of purposes, including retail packaging, gift packaging, and product packaging. They are particularly popular in the cosmetic and luxury goods industries because they offer a premium look and feel that enhances the perceived value of the products. The soft-touch lamination process involves coating the paperboard with matte plastic film.

This plastic film mixes with a special chemical compound that gives it a soft, velvety texture. The resulting finish is not only aesthetically pleasing but also adds a layer of protection to the packaging, making it more durable and resistant to wear and tear. Additionally, one of the key benefits of soft-touch laminated boxes is their ability to create a tactile experience for the consumer.

When you touch the box, the soft, velvety texture adds a sense of luxury and exclusivity to the product inside. Finally, the soft touch finish combines with other printing techniques, such as foil stamping or embossing, to create an even more striking visual effect.

Custom Soft Touch Laminated Boxes are a type of customizable packaging to meet the specific needs of a brand or product. Soft touch lamination is a finishing process that creates a velvety texture on the surface of the box, giving it a luxurious feel that enhances the perceived value of the product inside.

These boxes use high-quality materials, and the lamination protects against wear and tear, scratches, and other environmental factors that can damage the packaging or the product inside.

Soft Touch Laminated packaging is a popular choice for businesses that want to create high-quality packaging that reflects the value of their products. The luxurious feel of the Soft Touch Lamination can create a positive first impression for customers, and the custom design elements can help to differentiate the product from competitors on the shelves.

Additionally, the use of eco-friendly materials and sustainable production practices can help to reduce the environmental impact of the packaging, making it a more responsible choice for businesses that commit to sustainability.

Soft touch laminated boxes are famous for their unique texture and appearance, but they wouldn’t be possible without the right materials. In this article, we’ll explore the various materials used in the production of soft-touch laminated boxes and their properties.

Paperboard: Paperboard is the primary material used in the production of soft-touch laminated boxes. It is a thick, stiff, and durable type of paper that is common in packaging applications. Paperboard is available in a variety of thicknesses and grades, allowing specific packaging requirements. The primary advantage of paperboard is its strength and stiffness, which makes it an ideal material for creating sturdy packaging. Additionally, paperboard is relatively lightweight, which reduces shipping costs and makes it easier to handle.

Soft Touch Film: Soft-touch film is a special type of plastic film used to create the soft, velvety texture that is characteristic of soft-touch laminated boxes. The film uses polypropylene, which is a thermoplastic polymer that is famous for its strength and durability. To create the soft touch finish, the film gets a coat of a special chemical compound that creates a unique texture when it dries. This texture is what gives laminated boxes their distinct feel and appearance.

Adhesive: The adhesive bonds the soft touch film to the paperboard. The adhesive used in soft touch laminated boxes is typically a solvent-based adhesive, which means that it contains solvents that evaporate during the drying process. Solvent-based adhesives are common in packaging applications because they provide excellent bonding strength and are resistant to water and heat.

Foil Stamping: Foil stamping is a printing technique to create metallic or reflective designs on the surface of soft-touch laminated boxes. Foil stamping includes applying a thin layer of metallic foil to the surface of the box using heat and pressure. The foil used in foil stamping uses aluminum or other metals to create a reflective surface. Foil stamping creates intricate designs and patterns that add visual interest to soft-touch laminated boxes.

Embossing: Embossing is another printing technique to create raised designs on the surface of soft-touch laminated boxes. This process includes pressing the paperboard between two metal dies, which creates a three-dimensional effect on the surface of the box. Embossing creates a variety of designs, from simple logos and text to intricate patterns and images. The raised texture of embossed designs adds a tactile element to soft-touch laminated boxes, enhancing their overall appeal.

UV Coating: UV coating is a finishing technique to add a layer of protection to the surface of soft touch laminated boxes. This UV coating includes applying a thin layer of clear liquid coating to the surface of the box and then exposing it to ultraviolet light. The UV light causes the coating to harden and create a protective layer resistant to scratches, scuffs, and other forms of damage. UV coating also adds a glossy or matte finish to soft-touch laminated boxes, depending on the desired effect.

The manufacturing process of soft touch laminated boxes involves several steps that require precision and attention to detail. Let’s take a closer look at each step in the process:

Design and Printing: First step in manufacturing soft-touch laminated boxes is designing the box and printing the graphics. The design of the box will depend on the product, and the printing will typically include the product’s branding and any other necessary information. Printing the graphics on a large sheet of paperboard uses high-quality printing equipment. The printing process ensures that the colors are consistent and that the graphics are sharp and clear.

Soft Touch Lamination: After the graphics printing, the paperboard is ready for soft touch lamination. Soft touch lamination applies a thin layer of soft touch film to the surface of the paperboard. The film positions over the printed graphics, and an adhesive applies to the back of the film. The film presses onto the paperboard using a laminating machine, which applies pressure and heat to create a strong bond between the film and the paperboard.

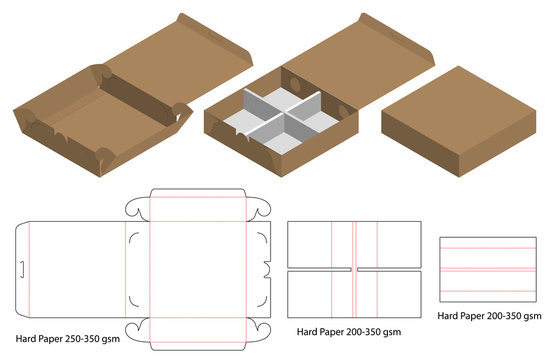

Die Cutting: After the soft touch lamination is complete, the paperboard die-cutting comes to cut it into the desired shape. Die cutting is the process of cutting the paperboard into the shape of the box using a specially designed die. The die is a metal plate to match the shape and size of the box. The die places into a die-cutting machine, which uses a combination of pressure and sharp blades to cut the paperboard into the desired shape.

Folding and Gluing: After the paperboard die-cutting, it folds and glues into the final shape of the box. This folding and gluing process ensures that the box is uniform and the sides are straight and even. The paperboard folds along pre-scored lines to create the sides of the box. The glue applies to the flaps, and the sides fold together to create the final shape of the box.

Foil Stamping and Embossing: If the box design includes foil stamping or embossing, these steps include the folding and gluing process. Foil stamping and embossing are both printing techniques that add texture and visual interest to the box. Foil stamping involves applying a thin layer of metallic foil to the surface of the box using heat and pressure. Embossing involves pressing the paperboard between two metal dies to create a three-dimensional effect on the surface of the box.

UV Coating: Final step in the manufacturing process of soft touch laminated boxes is UV coating. UV coating is a finishing technique that adds a layer of protection to the surface of the box. The UV coating applies to the surface of the box using a coating machine. The coating exposes to ultraviolet light, which causes it to harden and create a protective layer resistant to scratches, scuffs, and other forms of damage.

Soft touch laminated boxes are now famous for their unique and high-quality finish, which makes them stand out from other types of packaging. These boxes have a velvety texture that is soft to the touch, giving them a luxurious feel to the consumers. Here are some of the specialties of soft-touch laminated boxes:

Aesthetic Appeal: One of the most significant specialties of laminated boxes is their aesthetic appeal. The velvety texture of the box is visually appealing and adds a premium touch to the product. The soft-touch finish of the box creates a sophisticated and elegant look that is perfect for high-end products.

Durability: Soft-touch laminated boxes are also famous for their durability. The soft-touch lamination adds an extra layer of protection to the box, making it more resistant to wear and tear. This lamination also protects the graphics and prevents them from fading or peeling over time.

Scratch-Resistance: The soft-touch finish of the box also makes it resistant to scratches. This is especially important for products frequently handled or shipped long distances. The scratch-resistant properties of the box ensure that it maintains its aesthetic appeal, even after being exposed to rough handling or transport.

Non-Stick Properties: Another specialty of soft-touch laminated boxes is their non-stick properties. The soft-touch finish of the box makes it less prone to picking up dirt, dust, or fingerprints. This is especially important for products in retail stores or trade shows, where they handle multiple people.

Customizability: Soft touch laminated boxes are highly customizable, which is another specialty of this type of packaging. The graphics and design of the box are customizable to meet the specific needs of the product. The boxes can also be die-cut into any shape or size, making them ideal for a wide range of products.

Environmentally Friendly: Soft-touch laminated boxes are also environmentally friendly. The lamination process uses fewer chemicals than other types of lamination, which reduces the impact on the environment. The boxes are also recyclable, which makes them a sustainable option for companies that are looking to reduce their carbon footprint.

Marketing Benefits: Laminated boxes offer several marketing benefits as well. The premium look and feel of the box can help to increase the perceived value of the product, which can lead to higher sales. The customization options also make it possible to create packaging that aligns with a brand’s marketing message, helping to build brand recognition and loyalty.

Protection: Soft-touch laminated boxes also offer superior protection for the products they contain. The lamination helps to protect the contents of the box from moisture, dust, and other environmental factors that can damage or degrade the product. This makes soft-touch laminated boxes an ideal option for products that are fragile or sensitive to environmental factors.

Umbrella Custom Packaging offers a variety of options when it comes to soft touch laminated boxes for umbrellas. Here are some of the offerings:

We provide soft-touch laminated boxes which tailor to fit the specific size and shape. This means that the box which designs to fit the length, width, and height of the material, ensuring a snug and secure fit.

Our packaging company can also provide customized graphics and design options for soft-touch laminated boxes. This means the box with the brand’s logo, colors, and other design elements creates a cohesive and branded look that aligns with the company’s marketing message.

Soft touch laminated boxes are available in a variety of colors, which means that companies can choose a color that aligns with their brand identity or the color. This can help to create a cohesive and visually appealing look that is consistent with the company’s branding.

Soft-touch laminated boxes have protection features to keep the umbrella safe during shipping and handling. This can include features such as foam inserts, reinforced corners, or other custom-designed inserts to ensure that the umbrella protects during transit.

Soft touch-laminated boxes offer a variety of branding opportunities for companies. The box design elements create a consistent look and feel that aligns with the company’s marketing message. This can help to build brand recognition and loyalty among customers.

Our company also offers environmentally friendly options for soft-touch laminated boxes. This can include using recyclable materials or using fewer chemicals during the lamination process to reduce the impact on the environment. Our team commits to o sustainability and can choose packaging options that align with their values.

Soft Touch Laminated Boxes wholesale refers to the bulk purchasing soft-touch laminated boxes at a discounted price. Wholesale prices for customers who buy in large quantities, such as retailers or businesses that need packaging for their products, are profitable. Soft Touch Laminated Boxes wholesale are a cost-effective option for businesses that need packaging for their products in large quantities. Moreover, By purchasing in bulk, businesses can benefit from discounted prices, reducing the cost of packaging per unit. Additionally, businesses can maintain a consistent look and feel across all their products, which can enhance brand recognition and customer loyalty.

Copyright © 2023 UmbrellaPackaging All rights reserved.