Menu

Close

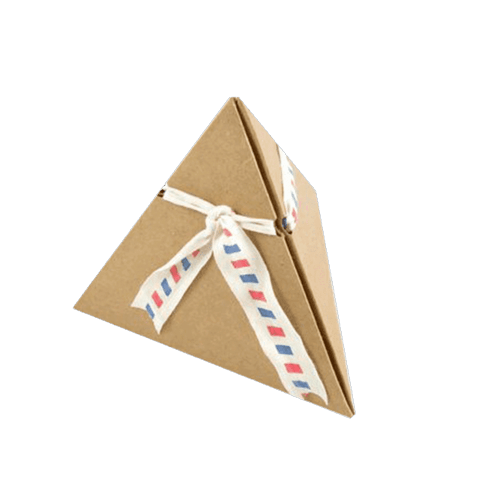

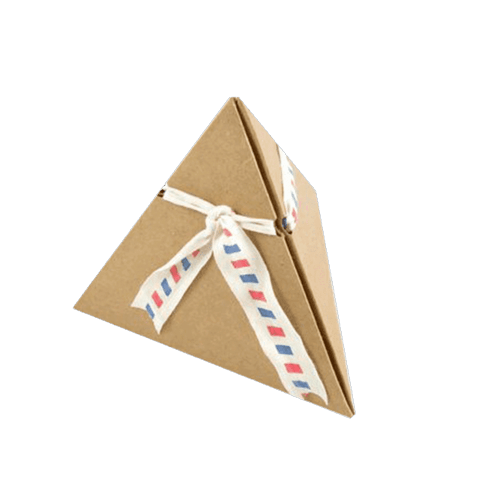

The triangular tube is a unique and innovative structure that has been gaining popularity in recent years. This type of tube is a three-sided tube that has many benefits and advantages over traditional cylindrical tubes. Tube usage is in various applications, including construction, transportation, and industrial processes.

| Sizes | Offered in all custom shapes and sizes |

| Paper Stock | 14pt, 16pt, 18pt & 24pt White SBS C1S C2S |

| Printing | Digital, Offset and Screen Printing |

| Options | Matte, Glossy, Spot UV, Aqueous Coating and Embossing, Debossing |

| Extras | Flaps, Ribbons, thread handles, gold foiling, silver foiling |

| Quantities | Short run and Bulk orders are accepted |

Payments:

![]()

| Sizes | Offered in all custom shapes and sizes |

| Paper Stock | 14pt, 16pt, 18pt & 24pt White SBS C1S C2S |

| Printing | Digital, Offset and Screen Printing |

| Options | Matte, Glossy, Spot UV, Aqueous Coating and Embossing, Debossing |

| Extras | Flaps, Ribbons, thread handles, gold foiling, silver foiling |

| Quantities | Short run and Bulk orders are accepted |

Payments:![]()

These tubes have a few unique features that make it different from traditional cylindrical tubes. Firstly, the three sided design provides greater strength and stability. Unlike cylindrical tubes, which can easily bend and deform under stress, the triangular design distributes the force evenly across all three sides. This makes it ideal for use in construction. The tube is also an excellent choice for use in areas with high seismic activity. Its three-sided design provides greater stability and resistance to earthquakes, making it more durable and reliable in earthquake-prone regions.

Triangular shipping tubes boxes are a type of packaging used to ship a variety of items, including posters, artwork, and blueprints. Their design is to protect these items during transit, ensuring they arrive at their destination in excellent condition. Triangular shipping tube uses a variety of materials, including cardboard, plastic, and metal, and come in a range of sizes to accommodate different items. When it comes to shipping fragile items such as artwork or posters, these tubes offer superior protection compared to traditional packaging materials. The triangular design provides greater strength and stability, reducing the risk of damage during transit. This is especially important for items that are one-of-a-kind or irreplaceable. In addition to their protective qualities, these tubes are also an excellent branding tool. The logos, graphics, and text make them an ideal choice for businesses looking to promote their brand during shipping. Customizing these tubes not only protects the contents but also creates a memorable unboxing experience for the recipient.

When it comes to the materials used for these tubes, there are several options available. The choice of material will depend on the specific application and the desired properties of the tube. The three main materials used for these tubes are metal, plastic, and composite materials. Metal these tubes are a popular choice for applications that require strength and durability. They are commonly used in construction, transportation, and industrial processes. Metal these tubes use a variety of metals, including steel, aluminum, and titanium. Steel these tubes are famous for their strength and resistance to corrosion, making them ideal for use in harsh environments.

These tubes are lightweight and offer good resistance to corrosion, making them ideal for use in aerospace and automotive applications. Titanium these tubes are strong and lightweight, making them an excellent choice for high-performance applications. Plastic these tubes are a lightweight and cost-effective alternative to metal these tubes. They are commonly used for shipping and packaging applications, as well as in construction and automotive industries. Plastic these tubes uses a variety of plastics, including polyethylene, polypropylene, and PVC. Polyethylene these tubes are lightweight and durable, making them ideal for shipping and packaging applications. Polypropylene triangular tubes are also lightweight and durable, with good resistance to impact and temperature changes. PVC tubes are strong and rigid, making them ideal for use in construction and architectural applications.

Composite materials are another option for these tubes. Composite material is a combination of two or more materials to create a material with specific properties. Their materials combine to create these tubes with superior strength, durability, and resistance to corrosion. They are commonly used in aerospace and automotive applications, as well as in high-performance sporting equipment. Carbon fiber composite tubes are lightweight and offer excellent strength and stiffness, making them ideal for use in high-performance applications. Fiberglass composite tubes are also lightweight and offer good strength and durability, making them an excellent choice for industrial and sporting applications. In addition to these main materials, these tubes also use natural materials such as bamboo or wood. These materials are sustainable and environmentally friendly, making them an ideal choice for sustainable construction and architectural projects.

When selecting the material for these tubes, it is important to consider the properties required for the specific application. Strength, durability, resistance to corrosion and temperature changes, and weight are all important factors to consider. The choice of material will also affect the manufacturing process and the cost of the tube.

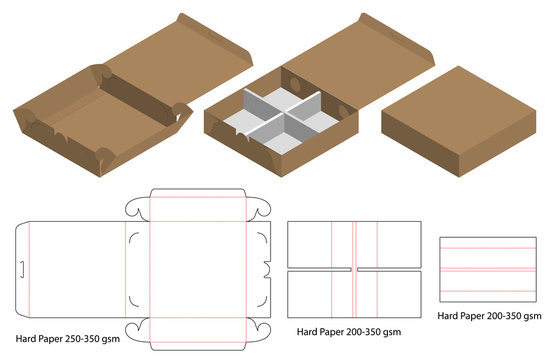

The manufacturing process for these tubes can vary depending on the material used, but there are some common steps involved in the process. For metal triangular tubes, the manufacturing process can involve extrusion or rolling. Extrusion is the process of forcing a material through a die to create a specific shape. For these tubes, they heats and then pulls a metal billet through a die with a triangular opening. Then is the cooling and cutting process to the desired length. Rolling, on the other hand, involves passing a metal sheet or plate through a series of rollers to gradually form it into a triangular shape. They weld the edges of the triangle together to create a tube. For plastic these tubes, the most common manufacturing processes are injection molding and extrusion. Injection molding involves melting plastic pellets and injecting them into a mold with a triangular shape.

Extrusion, on the other hand, involves melting plastic pellets and pushing them through a die with a triangular opening. They leave the plastic for cooling and cut to the desired length. Composite these tubes uses a combination of molding and curing processes. The manufacturing process starts with laying out layers of composite material, such as carbon fiber or fiberglass, in a mold with a triangular shape. The layers infuse with resin and places the mold in a press to compress the layers together. Regardless of the material used, there are several important steps involved in the manufacturing process.

These include Design and engineering: The first step in manufacturing a tube is to create a design and engineering specifications. This includes determining the size and shape of the tube, as well as the specific properties required for the application.

Material preparation: The material used for the tube cools into a triangular shape. This may involve heating or melting the material, as well as cutting it to the desired size and shape.

Forming: The material formation into a triangular shape using one of the methods described above. Finishing: After the tube has been formed, it may require finishing. This can involve grinding or polishing the surface of the tube to remove any imperfections.

Quality control: Finally, the tube there is inspection for quality control. This includes checking for any defects or imperfections, as well as ensuring that the tube meets the desired specifications. In addition to these steps, the manufacturing process may also involve other processes such as welding, painting, or coating the tube.

Triangular tubes are a specialized type of tubing that offer several unique advantages over other shapes. Their triangular cross-section makes them well-suited for a wide range of applications, including structural support, heat exchangers, and fluid transportation. One of the main advantages of these tubes is their strength. Because of their triangular shape, they are able to withstand higher levels of stress and strain than round or square tubes of the same size. This makes them ideal for use in structural applications. Another advantage of these tubes is their ability to resist deformation.

The triangular shape distributes the forces more evenly across the tube, which helps to prevent buckling and other forms of deformation. This makes these tubes a popular choice for use in applications that require high levels of stability and precision, such as telescopes and optical instruments. These tubes are also well-suited for use in heat exchangers. The triangular shape creates a large surface area, which allows for efficient heat transfer between the fluid flowing through the tube and the surrounding environment. This makes these tubes ideal for use in applications where precise temperature control requirement. In addition to their strength and thermal properties, these tubes also offer advantages in fluid transportation. The triangular shape reduces the amount of turbulence in the fluid flow, which can help to reduce pressure drops and energy losses.

This makes these tubes a popular choice for use in fluid handling applications, such as in the oil and gas industry. Another advantage of triangular tubes is their flexibility in design. Because of their unique shape, these tubes can be easily customized to meet the specific needs of a particular application. This includes the ability to vary the size, shape, and thickness of the tube to optimize its performance for a given application. Furthermore, these tubes are highly versatile and uses variety of materials including metals, plastics, and composites.

This means that they uses in a wide range of environments and applications, including corrosive environments, high-temperature applications, and even in aerospace and defense applications. These tubes also offer advantages in terms of cost-effectiveness. Because of their unique shape, they produces more efficiently than other types of tubing, which can result in lower production costs. Additionally, their strength and durability can help to reduce maintenance costs over the lifetime of the tube.

Umbrella Custom Packaging is a leading packaging company that specializes in creating custom packaging solutions for businesses of all sizes. We offer a wide range of packaging options, including highly specialized these tubes. Our tube packaging designs to provide businesses with a unique and functional way to package their products. We understand that each business has unique packaging requirements, which is why we work closely with our clients to create customized solutions that meet their specific needs. Our tube packaging is available in a variety of sizes and materials, including cardboard, corrugated cardboard, and plastic.

We can also customize the shape and design of the tube to ensure that it fits your product perfectly. In addition to our standard tube packaging options, we also offer a range of customization options to make your packaging stand out. This includes adding logos, graphics, and other branding elements to the tube to help promote your brand and create a strong visual impact. At Umbrella Custom Packaging, we understand that packaging plays an important role in the success of your business. That’s why we take great pride in providing our clients with high-quality packaging solutions. Our team of experienced packaging professionals dedicates to providing exceptional service and support to our clients at every stage of the packaging process. From initial design concepts to final delivery, we work closely with our clients to ensure that their packaging needs are met and exceeded.

We offer a range of additional services to help businesses streamline their packaging operations. This includes warehousing, fulfillment, and shipping services to ensure that your packaging delivers to your customers on time and in perfect condition. At Umbrella Custom Packaging, our commitment is to provide our clients with the highest level of quality, service, and support. Contact us today to learn more about our tube packaging options and how we can help you take your business to the next level.

Copyright © 2023 UmbrellaPackaging All rights reserved.